What Sets CLAF® Apart

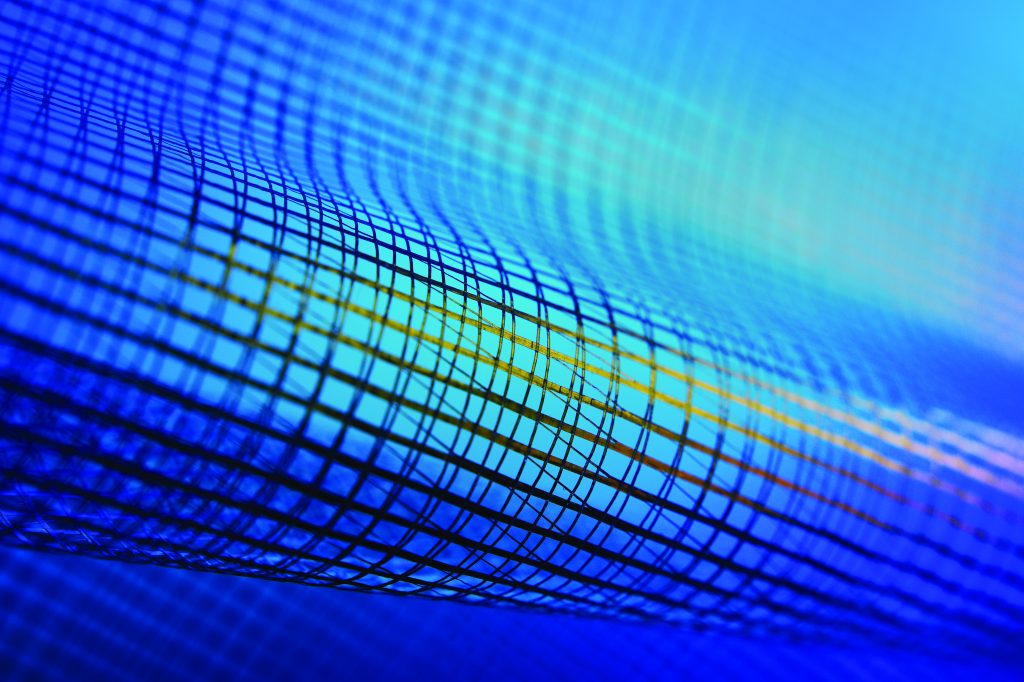

Strength & Reinforcement

Cross-laminated construction ensures superior tear resistance.

Breathability

Up to 70% open area for airflow and drainage.

Processability

Heat-sealable and bonds easily to films, foils, papers, and nonwovens.

Lightweight Efficiency

Provides stability without adding bulk.

Custom Options

Available in multiple weights, colors, and widths.

Engineered to Work for You

CLAF® is highly adaptable for converters and manufacturers. It can be laminated to films, foils, foams, and other nonwovens to create unique composites. With multiple weights and widths, up to 12 standard colors, and specialized versions like Double CLAF® and Metaclaf™, it offers nearly limitless design and performance flexibility.

CLAF® Bio Fabric™: Sustainable Mesh for a Better Future

For customers seeking a greener solution, CLAF® Bio Fabric™ delivers the same trusted performance as standard CLAF® with a sustainable twist. Made with up to 96% bio-based resin from sugarcane, CLAF® Bio is fully recyclable, USDA BioPreferred certified, and designed to support circular economy goals — without compromising durability, breathability, or processability.

Renewable Material

Made from 96% plant-based sugarcane resin, reducing reliance on fossil fuels.

Recyclable Design

Fully recyclable within polyethylene recycling streams, supporting circular use.

Proven Performance

Delivers the same strength and durability as standard CLAF®, so you don’t compromise on quality.

Certified Sustainable

Recognized under USDA BioPreferred and EU environmental standards, giving customers confidence in compliance.

FAQ

Can CLAF® be recycled?

Yes, CLAF® made in the US is composed entirely out of Polyethylene making it possible to be fully recycled in PE recycling streams.

Can CLAF® be bonded to other materials?

Yes, because CLAF® is made entirely with polyethylene resins – it can be bonded thermally to other PE-based materials such as films, foams, etc. CLAF® can also be thermally laminated to other materials like papers and foils. We also offer converting capabilities through our ANCI Composites location in Dalton, GA. Here we have the capabilities to thermal, sonic, and powder bond CLAF® to other materials.

Can CLAF® be produced using other polymers?

Yes, CLAF® can be made with PP (polypropylene) in various widths and styles.

Can CLAF® be slit to width?

Yes, CLAF® is made in 113″ widths and narrower widths can be achieved through a slitting process.

How is CLAF® different from other types of netting, scrims, and nonwovens?

CLAF® differs from other nonwoven netting and scrims because it is a lightweight and flat structure that behaves like a film during processing. This gives CLAF® the capability to heat seal and laminate easily to other poly films, papers, and itself.

Where is CLAF® manufactured?

CLAF® is manufactured in our Roanoke, Alabama facility (MADE in USA). We also have capabilities at our sister facility in Narita, Japan.

Discover What CLAF® Can Do for You

From packaging to construction and beyond, we’ll help you explore how CLAF® can deliver lightweight strength where it matters most.